Torque monitored thread tapping machines from Taurox

Taurox is manufacturer of torque-controlled thread tapping machines and tribometers and has been specializing in the field of thread processing since 2002. Our products are used worldwide and know how to convince users with their reliability, robustness and precision. In particular, our threading machines have proven themselves in use in industrial automation, where reliability, avoidance of tool breakage and reliable quality evaluation during machining have top priority.

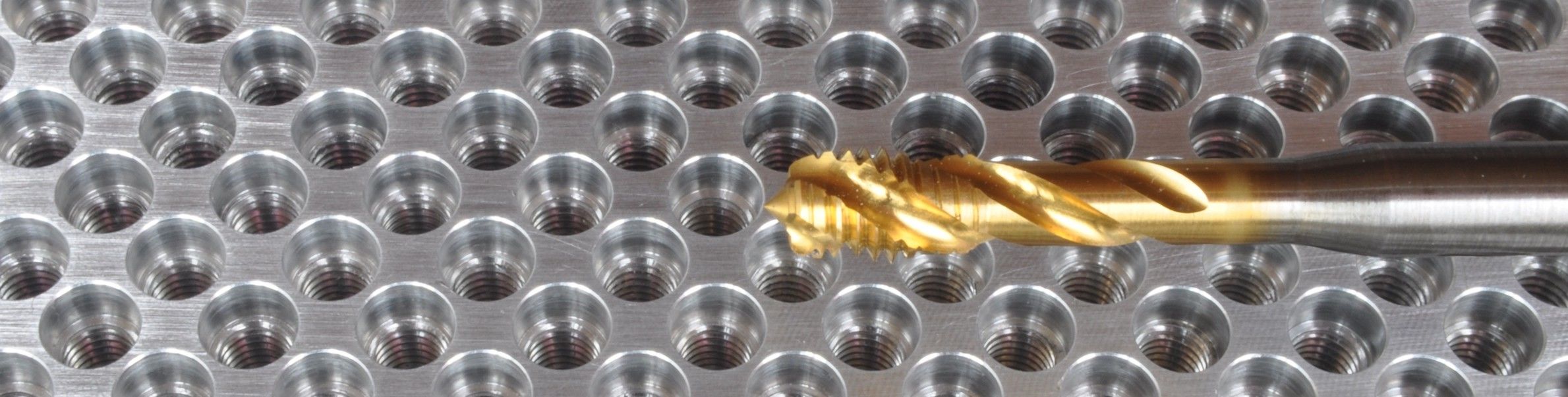

Thread tapping machines for inside threads

The thread tapping machines of the Tauro and Taurox product lines are designed for machining internal threads and offer a wide range of possible applications. The optimized machining programs for threading, thread forming, thread gauging and re-tapping through to the screwing in of threaded inserts and screws are specially developed for every purpose of our machines. Various, individually adjustable and parameterizable quality controls, such as the detection of air pockets or incorrect size of the boreholes ensure the integrity of your products.

The special advantage of the Taurox thread tapping machines:

The Taurox threading machines monitor all process sequences seamlessly during machining and therefore react even before a tool breaks off or the workpiece is damaged. Due to the high quality of the material processing and the possibility of integration into existing automation solutions, the Taurox products are suitable for use in a wide range of industries. This includes production and manufacturing companies from the areas of metal, plastic and sheet metal processing. Users from the supply and automotive industries, the aerospace industry, the optical industry and medical technology also benefit from the Tauro and Taurox threading machines.

Talk to us about your requirements!

We are specialists in the field of thread machining and offer you professional consulting and technical support with the integration of machinery plus intelligent implementation. Furthermore, we take the time to adjust and integrate the Tauro® and Taurox® products into your existing automation solution.

All advantages of Taurox thread tapping machines in a nutshell:

- Quality monitoring during tapping process

- Intelligent control and workpiece machining

- Smooth and reliable running performance

- Machining with carbide tools

- Continuously adjustable speed from 25 to 3000 rpm

- High dynamic due to synchronous servo technology

- Continuously adjustable torque from 0.03 Nm to 90 Nm

- Graphic display with a menu-guided user interface

- Modular design and PLC interface

- Useful for a variety of applications

- Robust and maintenance-free

Users convinced by Taurox thread tapping:

By exact monitoring, measuring and optimization of process parameters, our machines contribute to quality assurance during the machining process.

Without tool breakage and material rejects, production costs are decreased significantly with the Tauro and Taurox thread tapping machines.

Optimized process parameters increase tool life.